Aseptic cold filling equipment -- the best choice for vegetable protein beverage production

Market prospect of vegetable protein beverage

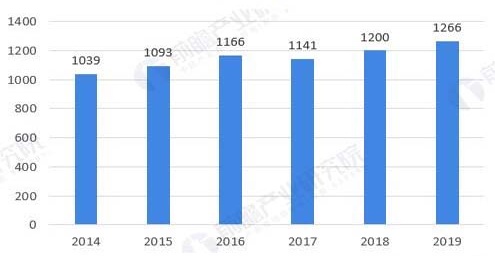

Vegetable protein drink is a kind of milk liquid drink with plant protein as the main body, which is made of plant kernel and pulp as the main raw materials (such as soybean, peanut, almond, walnut, coconut and hazelnut).With no or less cholesterol content, rich in protein and amino acids, moderate amount of unsaturated fatty acids, nutritional composition is more uniform characteristics, welcomed by consumers. Chart 1: Market size of Vegetable protein beverage industry in China from 2014 to 2019 (unit: 100 million YUAN)

Vegetable protein drinks get rapid development in our country in recent years, the main reason is that the large and medium cities of the continuous improvement of living standards and health awareness, and the demand of consumers has gradually shifted from carbonated drinks that simply satisfy heat and thirst to drinks with nutrition, health care and function, to say the vegetable protein beverage is at an optimal period of development.

Selection of filling production line for vegetable protein beverage

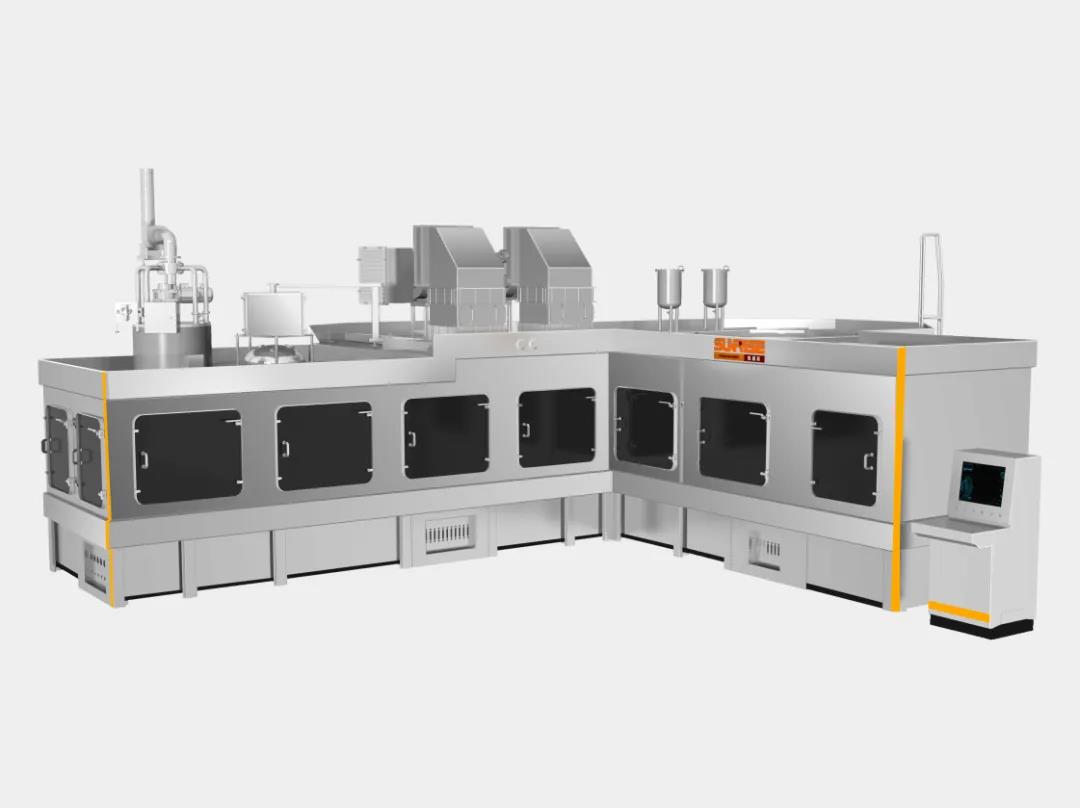

The quality of a drink is judged by three main factors: microorganisms, appearance and taste."To do a good job, it is necessary to sharpen its tools", to produce high-quality vegetable protein drinks, of course, there must be good equipment.How to choose the filling production line of vegetable protein drink?Aseptic cold filling production line is the best choice for vegetable protein beverage filling production.

Introduction to aseptic cold filling Aseptic cold filling is the cleaning and sterilization technology, sealing and isolation technology, microbial detection and control technology, air purification technology, filling and sealing technology, automatic control technology and other aspects of technology optimization, applied to acidic drinks, vegetable protein drinks, milk drinks and other production of advanced equipment.The equipment can expand the beverage filling process and maintain the nutrition composition, flavor and color of beverage products, especially for some thermal sensitive drinks.It provides wide space for diversified design of product appearance and reducing the cost of PET bottles.

苏公网安备32132302010360号

苏公网安备32132302010360号 QQ客服

QQ客服

拨打电话

拨打电话